Our Story

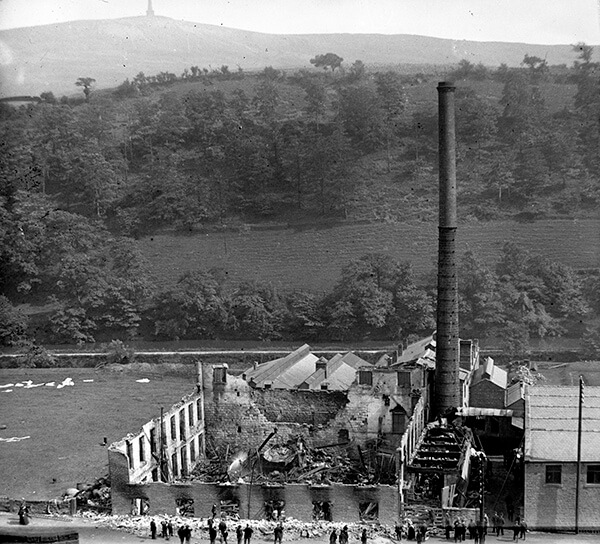

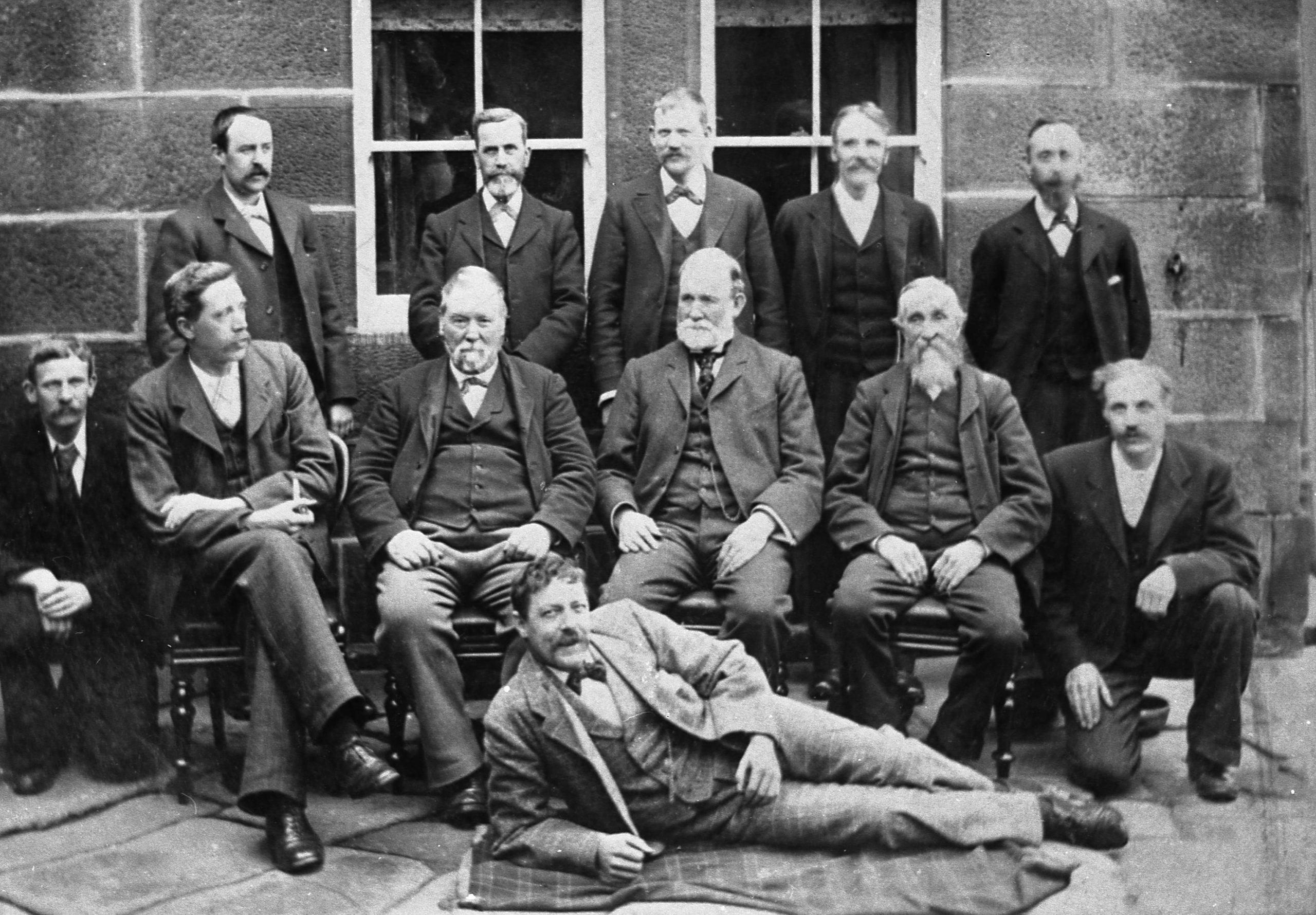

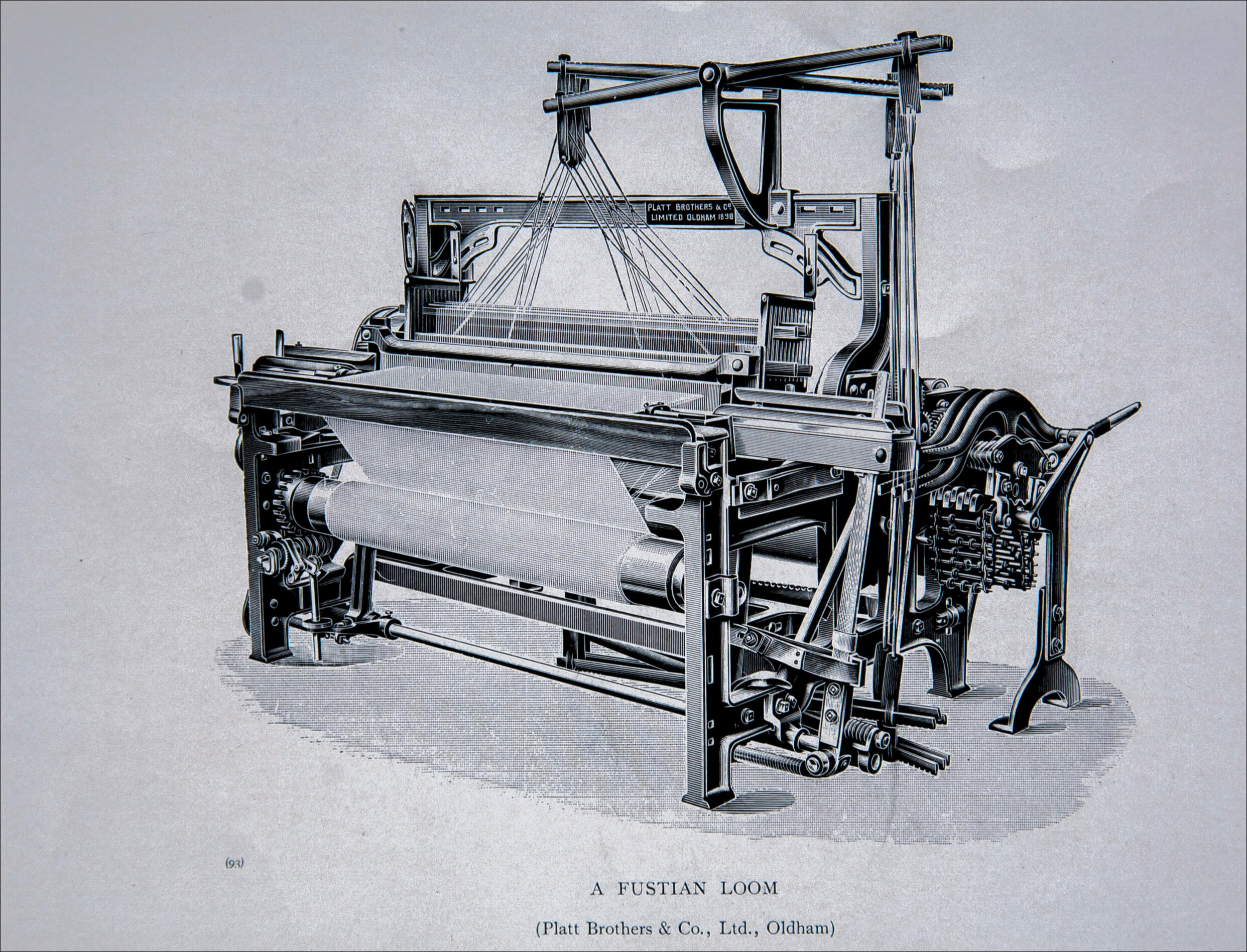

Moss Brothers Limited were weavers and converters of Corduroy and Moleskin fabric since the middle of the 19th century. Around the turn of the century and fearing the prospect of a monopoly in the dyeing trade from The English Velvet Cord Dyeing Company, Moss Brothers Limited who had the largest cutting and dyeing production in the district and several other local clothing companies came together, on 13th February 1901 The English Fustian Manufacturing Company Ltd was formed.

Over the following decades the EFMC became a fully vertical operation incorporating Spinning, Weaving, Dyeing, Clothing Manufacture and Retail outlets.

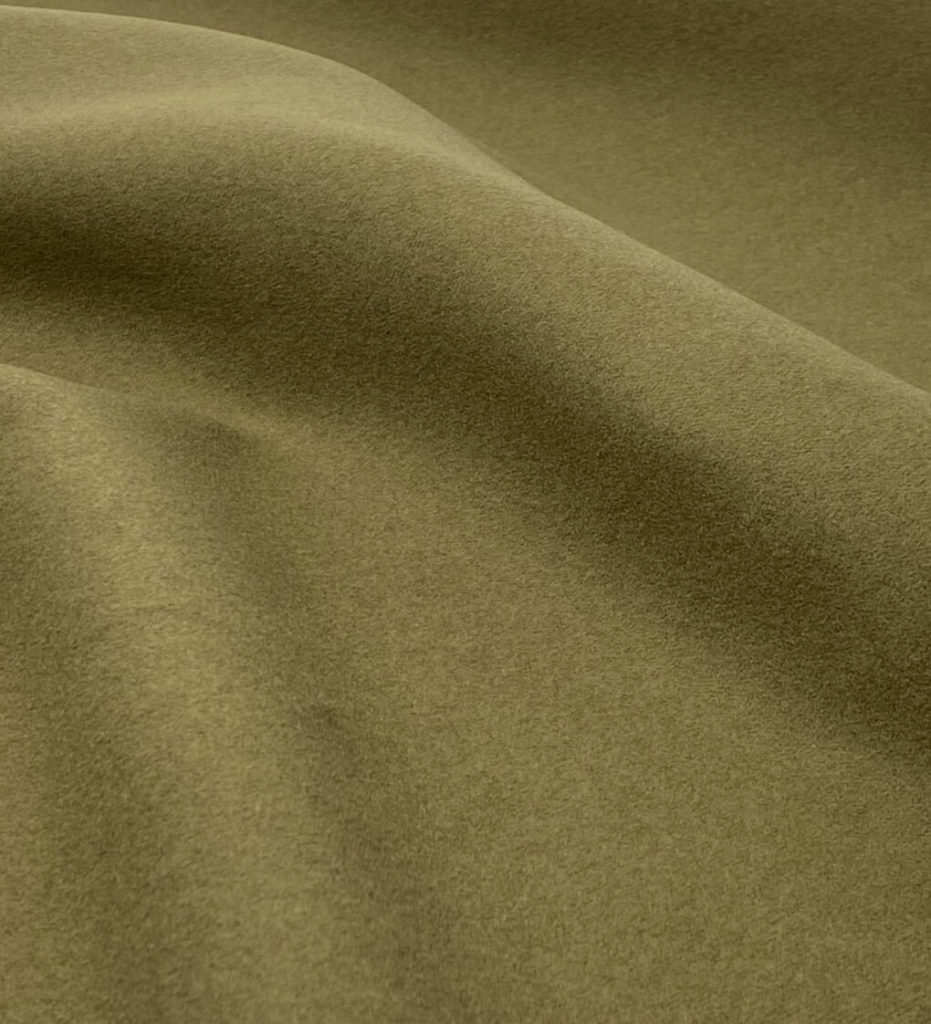

In 1970 Moss Brothers took over Brisbane Jones a local Velvet and Velveteen manufacturer and became known as Brisbane Moss Corduroys, in 1983 Brisbane Moss became part of the Chapman Group and launched a stock based fabric service, the relationship proved successful winning the Queens Award for Export in 2004 and 2012 with presentations at our factory and with Queen Elizabeth at Buckingham Palace. The awards show the importance of quality and traditional fabrics, highlighting the enviable worldwide reputation that Brisbane Moss has built over the years.

There have been many changes that have occurred within the Textile Industry and indeed Brisbane Moss has undergone a number of these and will continue to offer a range of traditional qualities from stock along with new and exciting fabrics for many years to come.

Corduroy and Moleskin Fabrics